Heat treatment equipment

Conduct simulated annealing and brazing tests to understand the actual use of the product at the client’s site.

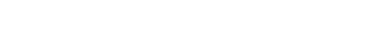

Desktop direct reading spectrometer

Accurately analyze the specific content of various elements in materials.

Oil testing equipment

Distillation range testing device (left 1), moisture detector (left 2), kinematic viscosity tester (right 2), and open cup flash point tester (right 1). It can detect oil from multiple indicators to ensure that the product production process is qualified.

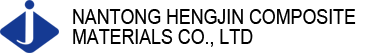

Electrochemical workstation

Measure the electrode potential of materials.

Scanning electron microscope

Perform failure analysis, microscopic morphology observation, energy spectrum detection, etc.

Salt spray test chamber

Conduct various salt spray tests such as neutral and acidic tests to understand the corrosion resistance of materials.

90-t soaking furnace (Manufacturer: Suzhou Longray Thermal Technology Co., Ltd.)

Equipment application: Homogenization treatment of aluminum and aluminum alloy ingots before sawing. Equipment composition: box type furnace body, air circulation system, diversion device, furnace door and lifting mechanism, furnace door sealing, heater, temperature measuring device, and control system

250-t vertical pushing aluminum ingot heating furnace (gas heating)

Equipment application: Heating for aluminum ingots (with cladding plates) before rolling. Process description: Feeding - heating - reclaiming